rockwell hardness test gif|Rockwell Hardness Test on Make a GIF : white label Browse MakeaGif's great section of animated GIFs, or make your very own. Upload, customize and create the best GIFs with our free GIF animator! See it. GIF it. Share it. webHer sons, Viljar Robert Christian Hanssen (born August 4, 1993) and Torje Hanssen (born July 14, 1997), were on the island of Utøya during the 22nd of July 2011 Norway attacks. Viljar was shot five times in the left hand, right thigh, left shoulder and head near his right eye. Their story on Utøya is featured in the 2018 movie 22 July.

{plog:ftitle_list}

Weight. 102 kg. Nationality. American. Hair Color. Dark Brown. Eye Color. Dark Brown. Gracie Bon is a Panamanian plus-size model who is widely recognized for the bikini and .

Browse MakeaGif's great section of animated GIFs, or make your very own. Upload, customize and create the best GIFs with our free GIF animator! See it. GIF it. Share it. The perfect Portable Rockwell Tester Animated GIF for your conversation. Discover and Share the best GIFs on Tenor. The perfect Portable Hardness Tester Portable Rockwell Tester Animated GIF for your conversation. Discover and Share the best GIFs on Tenor.

custom Evaporation Residue Testing

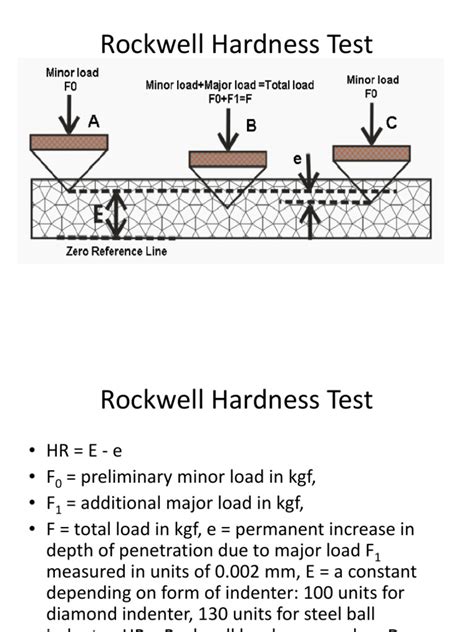

The Mohs Hardness Scale is a widely recognized and simple scale for measuring the scratch resistance of various minerals. Created by Friedrich Mohs, a German geologist, in 1812, it remains a standard in geology, .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a .Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the . The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. This test was .

In the Rockwell hardness test, an indenter is pressed into the material to be tested. The indentation depth serves as a measure of the hardness! The measuring process of the Rockwell test is carried out in three .

Hardness is defined as a material’s resistance to permanent indentation. Rockwell Hardness Test is one method of testing the hardness of a material and uses the Rockwell scale based on indentation hardness of a .In this article, we briefly explained the importance and application, advantages and disadvantages of Rockwell hardness test. We also introduce the Rockwell test with different indenter types, .What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared .

Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your .The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine . Rockwell Hardness Test is one method of testing the hardness of a material and uses the Rockwell scale based on indentation hardness of a material. History of the Rockwell Hardness Tester Hugh M. Rockwell (1890–1957) and Stanley P. Rockwell (1886–1940) from Connecticut co-invented the Rockwell Hardness Tester in 1919.The Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article.

A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should consider relevant standards, as well as the usual criteria when choosing between different types of hardness test.

Browse MakeaGif's great section of animated GIFs, or make your very own. Upload, customize and create the best GIFs with our free GIF animator! See it. GIF it. Share it. . Rockwell Hardness Test. 524. Added 5 years ago anonymously in meme GIFs Source: Watch the full video | Create GIF from this video. 0.These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to Rockwell Hardness Conversion Table The Rockwell hardness test involves making an indentation on the test material. The indenter is either a conical diamond or a steel ball. Indenter ball diameters range from 1/16 to 1/2 inches and are chosen based on the test parameters.

Rockwell hardness test is applied with the carbide balls to test softer materials such as construction steels or brass because if you test soft material with diamond cones, it could cause very deep penetration into the material which will go far outside from the specified depth of 0.2mm. With a carbide ball, the specified reference depth is .

Rockwell hardness testing can determine the hardness of most metals, alloys and plastics, ranging from the softest bearing materials to the hardest steels. Photo: Wilson Instruments, An Instron Company. Stanley P. Rockwell invented the Rockwell hardness test. As a metallurgist for a large ball bearing company, he wanted a fast, nondestructive . ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .

Indenters in a Rockwell hardness test are either hardened steel balls or a conical diamond. Two sets of loads cause an impact on the material surface, which include an initial minor load and a final major load. Additionally, the impact often causes an indentation on the material surface, and measuring the depth of this indentation helps to .Load: The Rockwell hardness test uses a pre-load of 10 kgf, followed by the application of the main load, which varies depending on the Rockwell scale being used (e.g., 60 kgf for the Rockwell A scale, 150 kgf for the Rockwell C scale). The load is applied for a . Basic principle and practical procedure of the Rockwell hardness test - Testing machine, test piece, conical diamond indenter - Basic principle, hardness d.The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on surfaces with moderate roughness, making it a practical choice for a wide range of materials and surface conditions.

Hardness test methods in the macro range include Brinell, Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf and 5 kgf (test load ≥ 0.2 kgf and < 5 kgf). . The concept of the Rockwell Hardness test is essentially similar to its counterparts. A sample material is fed on to either a digital or manual Rockwell hardness tester which would then drop a set load ending with an indenter on the surface. Then, the strength of the material will be determined by the nature of the indentation left on the sample. The Rockwell Hardness test is a widely used method to determine the hardness of metallic materials, thanks to its simplicity and quickness. This hardness test is based on indentation and depth of penetration, and it can be performed on various metals, including aluminum, copper alloys, brass, soft steels, and hard carbon steels. . The perfect Portable Rockwell Tester Animated GIF for your conversation. Discover and Share the best GIFs on Tenor. Tenor.com has been translated based on your browser's language setting. . #Portable-Hardness-Tester. #Portable-Hardness-Tester. #Ultrasonic-Hardness-Tester.

bespoke Evaporation Residue Testing

Rockwell Hardness Test . In the Rockwell test the depth of the indenter penetration into the specimen surface is measured. The indenter may be either a hardened steel ball with diameter 1/16”, 1/8” or a spherical diamond cone of 120º angle (Brale). Loading procedure starts from applying a minor load of 10 kgf (3kgf in Rockwell In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 mm serves as the indenter. The indentation depth can be read directly from a dial gauge via the traverse path of the testing machine.In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter is measured. In contrast, the indentation size is measured in the Brinell, Vickers and Knoop optical test methods.The hardness of Fine Ceramics is generally indicated using a Vickers hardness number. The method for measuring the hardness of Fine Ceramics is defined in JIS R 1610 (ISO 14705: 2000). Vickers hardness is a resistance value obtained by pressing a .

Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common Rockwell variants include: HRC – Known as “Rockwell C,” a 150 kgf load is applied via a diamond in this method.The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. With every test, two loads are applied to the test subject. First, an indenter is forced into the test subject under an initial load of 10kg-f, and the depth is recorded.

MP4 GIF. 0. Rockwell Hardness Test. 3556. Added 9 years ago amiraae in action GIFs Source: .

What is a Rockwell Hardness Test

private label Evaporation Residue Testing

What are the Advantages and Disadvantages of the Rockwell

Rockwell hardness test

CrazyGames features the latest and best free online games. You can enjoy playing fun games without interruptions from downloads, intrusive ads, or pop-ups. Just load up your favorite games instantly in your web browser and enjoy the experience. You can play our games on desktop mobile devices.

rockwell hardness test gif|Rockwell Hardness Test on Make a GIF